Add to Cart

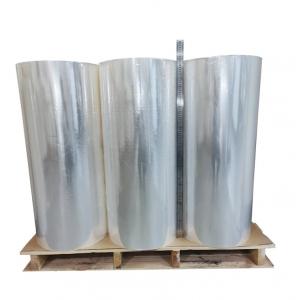

Biaxially oriented PET film (BOPET Film) is used successfully in a wide range of application, due to its excellent combination of optical, physical, mechanical, thermal

Specifications

| Properties | Unit | Typical value | |||

| Thickness | Micron | 36 | 50 | 75 | |

| Elongation at break | MD | % | 130 | 140 | 150 |

| TD | % | 120 | 130 | 130 | |

| Coefficient of triction | Static | -- | 0.40 | 0.40 | 0.40 |

| Dynamic | -- | 0.38 | 0.38 | 0.38 | |

They are clear, flexible, transparent or translucent material produced from PET polymer, a linear, thermoplastic polyester resin. PET film is a high-performance polymeric film and is generally more expensive than other polymeric films with several unique properties that are required for various end-uses. PET film has certain inherent desirable qualities such as high tensile strength, durability, heat resistance, good gas-barrier properties, dimensional stability, chemical inertness and clarity. PET film is available commercially in a range of widths, thicknesses and properties depending upon the needs of end users. It can be made as a single layer or can be coextruded with other co-polymers into a multilayer film encompassing the desired characteristics of each material. The distinct physical properties of the various types of PET film can be imparted into the product either during the polymerization of the PET resin, by the addition of chemicals such as slip modifiers (surface modifiers) or color additives, or subsequently during the PET film production process where various surface finishes may also be imparted by externally treating the films' surface(s).The biaxial orientation of the PET film makes it suitable for such applications as food packaging, electrical insulation, and printing sheets by increasing the product's crystallinity and thereby improving its tensile strength, heat resistance, and gas-barrier properties.

Basic Films---Metallizing---Coating---Slitting---Packing---Loading

Qingzhou Tianbao machinery technology Co., Ltd is always keeping the perception to make a combination of quality and credit with technological innovation, and make this intopractice to continually update new products.

Our company specialized production square, circular vacuum coating machine and various high-gradetypes food, medicine appropriative aluminum films such as CPP,PET,PVC,BOPP,PE etc.

They are widely used in cigarette packet, beer trademark,medicine bag, food packaging, automobile film, laser anti-counterfeiting,electromagnetic shielding, gold silver wire, reflective material and more other fileds.

Our company have a packaging material factory with an annual output of 10,000 tons of aluminized film and this is our practice base for researching, designing and producing high-grade vacuum coating machines.

Qingzhou Tianbao machinery technology Co., Ltd unremitting efforts to makes more contributions to the global customers!

Q1:The difference between vacuum coating machine and sputtering coating?

A: Vacuum sputter coating is more uniform than evaporative coating

Q2:Can i visit your factory?

A:Yes, welcome to visit our factory, Address: 3988. Tokyo Road Economic development zone Qingzhou city,Shandong province,China (Mainland)

Q3:How do you control your quality?

A:Each process will be tested by our own inspection department to make sure the product quality.